NPI CORP

N P I C O R P

MATERIALS

NPI Corp. manufactures a variety of products using stainless steel, aluminum, brass, Metalphoto®, vinyl, Mylar (polyester), Lexan (polycarbonate), rigid vinyl, and polystyrene. These materials are used in various industries for a range of applications, both in normal and harsh environments.

MATERIALS

NPI Corp. manufactures a variety of products using stainless steel, aluminum, brass, Metalphoto®, vinyl, Mylar (polyester), Lexan (polycarbonate), rigid vinyl, and polystyrene. These materials are used in various industries for a range of applications, both in normal and harsh environments.

Aluminum

Aluminum is lightweight and strong; withstands extreme temperatures and outdoor exposure; and has a high resistance to oxidation, abrasion, rust and corrosion. Aluminum is not recommended for salt water/spray environment.

Available in a variety of gauges & alloys

Vendor Tags, Identification Plates, Product Identification, Model & Serial Plates, Warning & Instructional Plates, Inventory & Asset Tags

Not recommended for salt water/spray environment

Thickness

.003″ to .125″

Brass

Brass can withstand extremes in temperature, salt-spray, continuous outdoor exposure, is explosion proof, and will continue to look great years after it is first produced.

Extremely durable

Easily cleanable with common household cleaners

Best suited for indoor use

High-end commercial

Luxury items

Excellent for decorative applications

Explosion proof

Thickness

.016″ to .125″

Stainless Steel

Stainless steel can withstand extremes in temperature, salt-spray, continuous outdoor exposure, and will continue to look great years after it is first produced, as it retains sheen and withstands abrasion. It is extremely durable and is resistant to chemicals, solvents, oxidation, rust, and corrosion.

Available in a variety of gauges & alloys

Vendor Tags, Identification Plates, Product Identification, Model & Serial Plates, Warning & Instructional Plates, Inventory & Asset Tags

Best for harsh outdoor and indoor environments, as well as salt water/spray environments.

Thickness

.018″ to .105″

Vinyl

Vinyl is an economical, non-laminated polyester, well-suited for surface printing with good chemical and abrasion resistance. As a label stock, vinyl is known for softness and malleability, and high conformability. When used as a custom label, it has superior printability, scuff resistance, and weather & UV resistance. It adapts easily to curved or irregular surfaces, is cost effective, has up to five years expected life, and has the widest variety of product applications.

Product Branding, Warning & Caution Decals, Vehicle Wraps (full & partial), Food Labels, Promotional Graphics, Fleet & Marine Markings, Signage, and Decals.

Used widely for promotional, outdoor, and industrial labels. Vinyl is perfect for vehicles, construction and equipment labels.

Thickness

.002″ to .030″

Mylar (Polyester)

Mylar is a strong laminated polyester film, very well suited for sub-surface printing. It is used similarly to polycarbonate nameplates, except it is more chemical resistant, more tear resistant and can stand up to the elements much better. Polyester decals are durable, clear and are resistant to shrinking or stretching. It is well known for exceptional clarity; strong heat, tear and abrasion resistance; and resistance to solvents, oils, and many chemicals. Polyester/Mylar comes in many thicknesses and as an over-laminate. A variety of adhesives are available for polyester.

Up to 7 year life expectancy

Top or back printed – ideal for both indoor & outdoor use

Switches, panels, decals, product identification, clear window graphics, informative labels and panel overlays are just a few common uses for Mylar.

Ideal for outdoor, industrial, commercial and waterproof labels.

Thickness

.001″ to .030″

Lexan/Polycarbonate

Lexan is a versatile and durable plastic that provides great strength at a light weight. Available in a variety of finishes & textures in combination with specialty bonding adhesives. It is also a laminate to provide heat, color, corrosion, and UV protection. Because they are easy to die cut, and print, polycarbonate offers product designers more freedom than some other materials.

Maximum durability

Excellent light transmission

High chemical resistance

High corrosion resistance

High temperature resistance

Suitable for sub-surface printing

Widely used for projects including switches, panels, decals, product identification, dials, aircraft markings, labels and panel overlays, and more!

Best for harsh indoor and outdoor use.

Thickness

.005″ to .060″

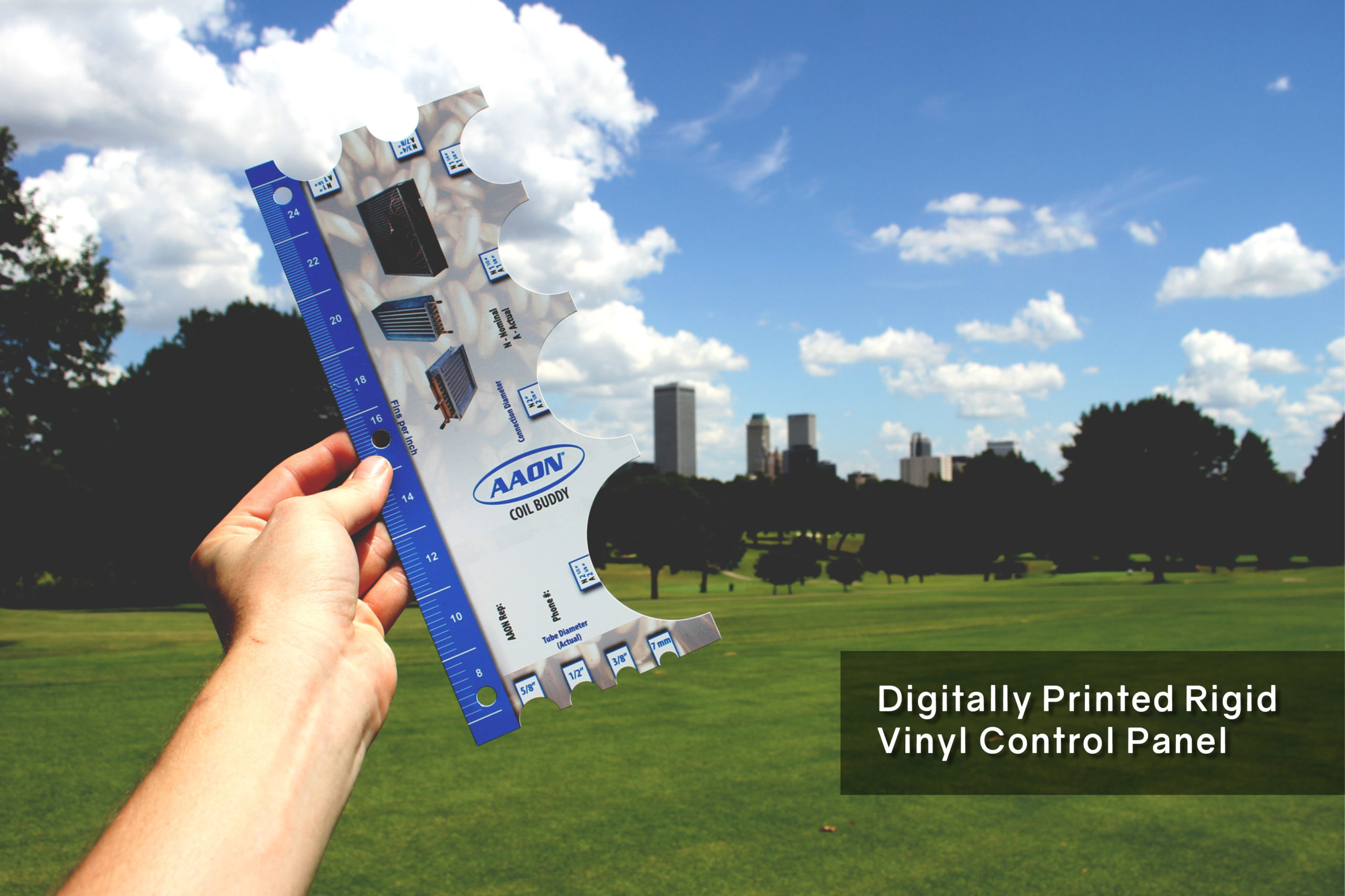

Rigid Vinyl

This type of plastic print stock is popular due to its flexibility, thin gauges, durability and value. Rigid Vinyl maintains high aesthetic quality and dimensional stability, with a low variance for consistent prints. Rigid Vinyl accepts ink and color well, with nice embossing retention.

Ideal for use in applications where high cost or the possibility of corrosion limit the use of a metal.

For exterior applications, rigid vinyl resists cracking in cold applications. Additionally, rigid vinyl impresses in outdoor environments, thanks to its resistance to ultraviolet rays.

Thickness

.002″ to .030″

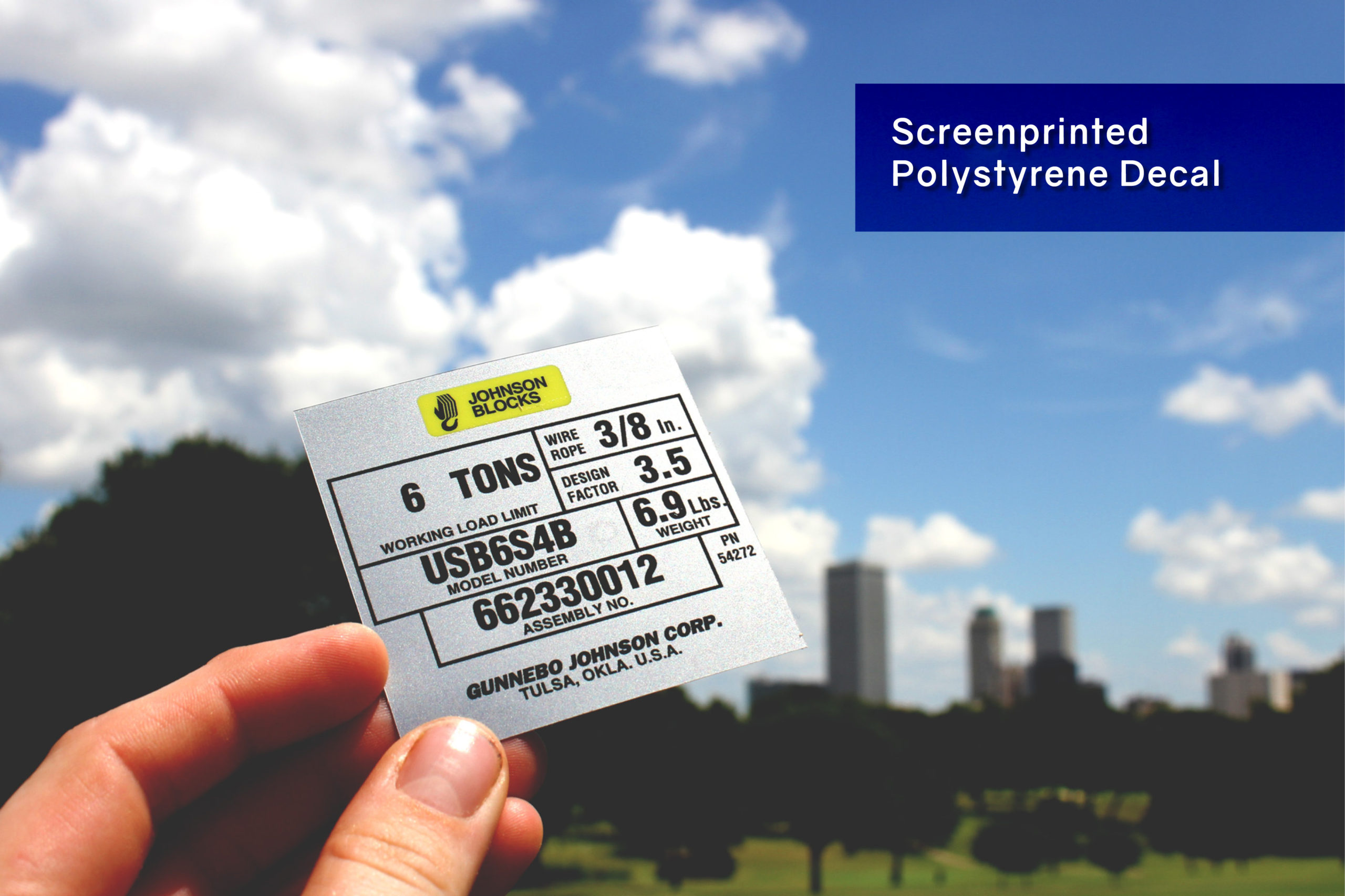

Polystyrene

A lightweight rigid foam with inexpensive resin options. Maintains a clear and shiny quality.

Indoor and outdoor signage, art display, exhibition boards, interior decoration.

Thickness

.010″ to .060″

Metalphoto®

Used to make durable, high-resolution nameplates, labels, control panels, and signs that don’t fade or chip. It’s extremely durable, with resistance to high temperatures, abrasion, and corrosion. Recommended for military applications and harsh indoor and outdoor environments, including salt water/spray environments.